Delivery chains in automotive manufacturing run smoothly

Depending on the model and make, an average car consists of roughly 30,000 parts.

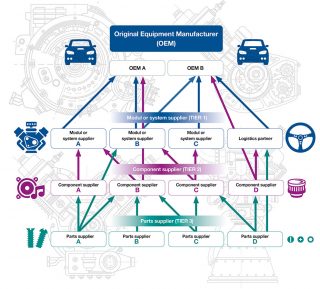

Most automakers do not make all these parts themselves but have them supplied by numerous companies exactly as needed. The pyramid of suppliers and subcontractors consists of several levels (Tier-1, Tier-2 etc.) and requires all involved parties to work together to perfection. Luckily, Electronic Data Interchange (EDI) is there to help and connect all parties with each other.

While Austria makes no cars, our country is home to roughly 900 automotive suppliers whose products are widely appreciated by OEMs (original equipment manufacturers) around the world. Among others, Austria has competence centers for developing engines and manufacturers of control devices, aluminum components, and sintered parts, to name just a few. In addition to independent suppliers, some OEMs have production facilities whose local subsidiaries manufacture essential parts in Austria. Some international automotive suppliers have plants where entire cars are assembled on behalf of OEMs. Since vehicles consist of roughly 30,000 parts, it is hardly surprising that many different suppliers are involved in the process. For things to run smoothly, sophisticated supply chain management is needed, which we will discuss in today’s blog post.

Sophisticated supply chain

As the diagram below shows, the OEM supply chain consists of several so-called tiers, or levels. Direct suppliers to OEMs are called Tier 1 suppliers. Let’s assume that “Parts manufacturer B” produces screws and delivers products to “Component manufacturer A” and directly to an OEM. This means that “Parts manufacturer B” works both at the Tier 3 and at the Tier 1 level.

Tier 3 suppliers could be called subcontractors to the Tier 2 level. Whenever such a subcontractor also delivers directly to an OEM, it is regarded as a Tier 1 company for such business transactions.

A thorough understanding of the logic behind the multi-tier system is helpful for analyzing the structure of the Austrian supplier industry. In Austria, 74 percent of all automotive suppliers (according to data by the Working Group Automotive Supplier Industry) work at Tier 2, meaning that they supply products to Tier 1 companies. At the same time, 61 percent of suppliers work at the Tier 1 level, meaning that they supply to OEMs. Some of these areas overlap.

EDI improves data quality

Companies that supply directly to OEMs face a situation that is now standard in the industry. Any company that strives to have or build a business relationship with an OEM is encouraged to use Electronic Data Interchange (EDI). Specifically, this is about the permanent exchange of documents such as orders, forecasts, call-offs, and invoices. Nowadays, without the use of EDI, it is actually impossible to deliver goods to an OEM production facility. This preference for EDI is well founded because EDI ultimately improves data quality, planning security, and cost efficiency along the entire supply chain for all involved partners.

Straightforward connection

Oftentimes, when it comes to establishing a connection to an OEM, many different options exist. Some OEMs have created dedicated EDI portals for their suppliers. Other suppliers integrate EDI into their ERP systems (enterprise resource planning), which allows them to connect to their clients’ inventory management programs.

EDITEL has been using its EDI data hub eXite to connect businesses in the automotive industry for decades. This approach significantly reduces technical complexity because it only requires a single connection and there is no need to program numerous interfaces. After all, individual automotive suppliers oftentimes have clients from many different countries who use inventory management programs from different providers. At the same time, buyers of automotive parts and components are not connected to a single supplier alone, but to several.

In daily business, Electronic Data Interchange is standard practice not only between Tier 1 suppliers and OEMs. Tier 1 suppliers are also greatly interested in getting connected to their own suppliers (Tier 2) via EDI . Whenever a business launches a digitalization project, something akin to a “chain reaction” follows, prompting all business partners to embrace EDI as well. This goes from Tier 3 suppliers all the way to Tier 1 suppliers, OEMs, car dealerships, and even production facilities. Thanks to this approach, high data quality without any system inconsistencies can be achieved, which not only saves time and money, but also leaves less room for error.

Tailor-made solutions available

If a business wants to adapt a dedicated web portal to its suppliers’ needs and make it available to them, this can certainly be done as well. If you are interested in such a solution, please get in touch with EDITEL. A different approach is also available: via web EDI, we can provide swift and easy access to Electronic Data Interchange to suppliers who do not yet have an EDI infrastructure in place. For a company to start sharing documents with its business partners via Electronic Data Interchange, all that is needed is a PC with internet access as well as login information.

To sum things up: no matter where in the supplier pyramid a company is located, whether it is headquartered in Austria or abroad, and whether it has adequate interfaces in its ERP system or not, plenty of options for all needs exist. The only non-option is to do nothing. Without EDI, especially small automotive suppliers will struggle to meet the demands of large players on the market in today’s globalized world.

If you would like to learn more about taking your automotive supply chain processes to the next level with the use of EDI, my colleagues and I will be more than happy to answer any questions you might have. Please use the contact box on the right to send us your message.

About the author

Andrea Kraft

Business Development Manager at EDITEL Austria

About EDITEL

EDITEL, an EDI service provider, is the internationally leading provider of EDI solutions (EDI = Electronic Data Interchange). The company specializes in the optimization of supply chain processes for companies of all sizes and in all industries.

Portrait photo copyright Editel/Petra Spiola

Symbol photo copyright iStock, copyright Atstock Productions

chart copyright EDITEL Austria GmbH